Project lead: Stephen Eick

Purpose

The purpose of this project is to provide Garage Physics with a low-cost, high-quality CNC router.

Introduction

The CNC router to be constructed is the OX. This particular 3-axis (X, Y, and Z) router was selected due to its relatively-low cost, sturdiness, and flexible build size.

Hardware

Item |

Quantity |

Part Link |

Item |

Quantity |

Part Link |

V-Slot 20x80mm (1500) |

2 |

V-Slot 20x60mm (1500) |

2 |

||

V-Slot 20x40mm (1500) |

4 |

V-Slot 20x40mm (250) |

1 |

||

Solid V Wheel Kit |

28 |

90 Degree corner bracket |

8 |

||

5 hole 90 degree joining plate |

4 |

Universal L brackets (double) |

4 |

||

Aluminum Spacers (1-1/2") |

3 |

Precision Shim |

40 |

||

Eccentric Spacers (1/4" Full Size) |

13 |

Threaded Rod Plate (Nema 17) |

2 |

http://openbuildspartstore.com/threaded-rod-plate-for-nema-17-stepper-motor/ |

|

Flexible Coupling (5mm x 8mm) |

1 |

8mm Threaded Rod (250mm) |

1 |

||

Lock Collar (8mm) |

2 |

Bearing (8mm) |

1 |

||

GT3 Timing Belt |

7 |

Socket Head M5 Screws (65mm) |

1 |

||

OX Plates |

1 |

Acme Nut Block 8mm |

1 |

http://openbuildspartstore.com/nut-block-for-8mm-metric-acme-lead-screw/ |

|

GT3 Timing Pulley |

3 |

http://openbuildspartstore.com/gt3-aluminum-timing-pulley-20-tooth/ |

M5x15mm Low Profile Screws |

2 |

|

M5x30mm Low Profile Screws |

2 |

M5x45mm Low Profile Screws |

1 |

||

M5x8mm Low Profile Screws |

2 |

M5x20mm Low Profile Screws |

1 |

||

M3x45mm Cap Head Screws |

4 |

5mm Locknut |

12 |

||

M5 Tee Nuts |

2 |

1/8" Spacers |

12 |

||

1/4" Spacers |

17 |

V-Slot Spacer Block |

2 |

Electronics

Still under development...

Item |

Link |

Nema 23 Stepper |

|

Nema 17 Stepper |

|

Stepper Driver Boards |

https://www.servo2go.com/product.php?ID=100434&cat=10021&sub=10003 |

12V/30A PSU |

http://openbuildspartstore.com/12v-30a-power-supply/ |

40x40mm x 10 12v fan |

http://www.amazon.com/dp/B000LB0M8S/ref=cm_sw_su_dp |

||Cable ||http://openbuildspartstore.com/16-2-project-wire/ ||dgerloop.slack.com/

Controlling the router

A Single Stepper

The first order of business is achieving control of a single stepper motor. Here's a bunch of links that were very useful while working through this:

https://www.servo2go.com/support/downloads/3540MUserManual.pdf

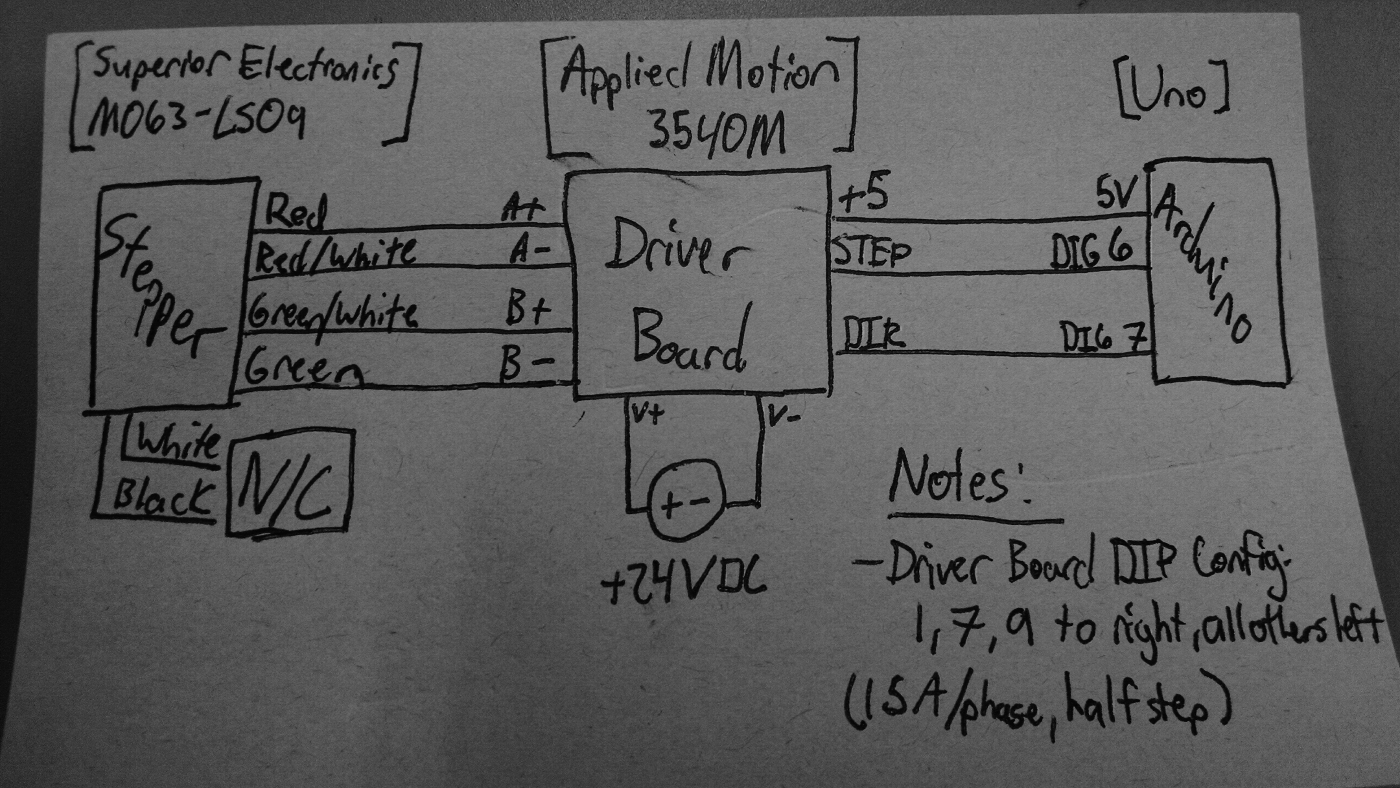

Connecting the stepper to the driver board (see page 9)

Stepper motor ratings (see page 17)

Here's a block diagram of the test setup used:

Some of the quirks discovered in testing:

- The safe stepping period range is 300-1200 microseconds.

Starting the stepper at a power-up with a stepping period of <300us does not work.

- The stepper was able to operate down to 200us by progressively lowering the period. If power is always maintained, then one could potentially operate the stepper at that fast of a stepping frequency.

- Above 1200us, the stepper experiences severe vibrations. Mounting it to a bracket should solve this.

- The driver board was configured to use 1.5A/phase and half-stepping.

Coming sort of soon...

Operating the router

Coming not too soon...