Goal:

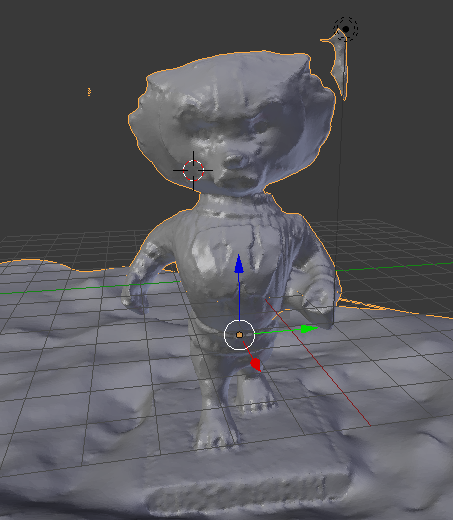

The goal of the 3D printer personal recycling demonstration project is to recycle a plastic container by forming chips into filament and us a 3D printer to reuse the filament. Using research in turning photos into 3D design files, a target is to 3D print a Bucky Badger.

Links:

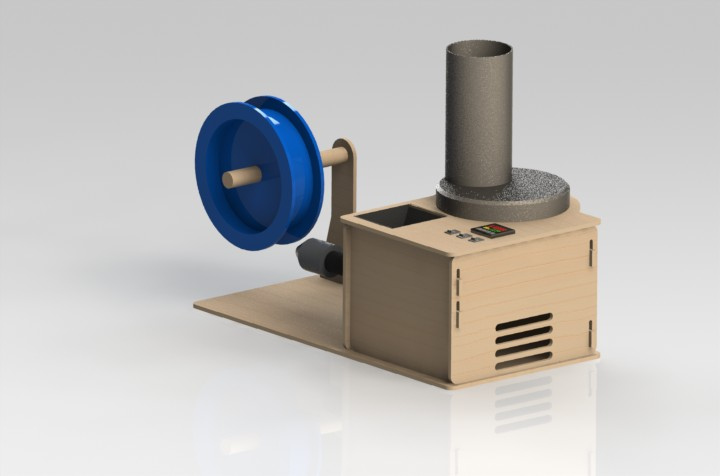

This link describes a project to build a machine to grind down plastics into filament that is usable for printing. The project also describes which plastics are usable for recycling and which may prove more difficult for printing. This project has received over thirty thousand dollars for funding from private donators, indicating that there is an interest for these sustainability printing projects.

Filabot http://www.greentechmedia.com/articles/read/3-d-printing-a-recycling-machine, http://www.wired.com/design/2013/01/filabot-plastic-recycler/, https://twitter.com/Filabot, http://gigaom.com/2013/02/04/filabot-makes-3d-printing-ink-out-of-your-plastic-recyclables/, http://www.gizmag.com/filabot-plastic-recycling/25848/, http://hackaday.com/2013/11/22/diy-filament-the-filabot-wee/

Harvesting waste plastic http://www.treehugger.com/clean-technology/harvesting-waste-plastic-reduce-poverty-plastic-bank.html

DIY plastic recycling machine http://www.treehugger.com/sustainable-product-design/precious-plastic-diy-plastic-recycling-machine-dave-hakkens.html

Equipment:

1. Plastics for recycling

2. 3D printer

3. Filabot Parts:

-Drill Bit

-Thermal Conducter Ring

-Insulation

-Motor

-Thermal Sensor

-Hopper Assembly

-Outside Shell

-Dye

What is a "Filabot"?

"Tyler McNaney, a student at Vermont Technical College, debuted the Filabot, a machine that repurposes plastic at home. The tabletop device grinds and melts most recyclable plastic into the raw filament used in 3-D printers."(Dillow 25)

Progress

(as of 12/2) Have spoken to URS about funding and have begun planning the process of turning the plastic into a filament appropriate for printing. Spent time studying 3D printing and the process of filaments as well as previous ideas regarding recycling and 3d printing. There are some discrepancies as to exactly what plastics can be recycled to create filament. Likely, the plastic in question is 01 PET/PETE which are easily broken down and melted. If printing a machine to break down the plastic bottles is a possibility then we will likely do so. If not then we are devising a way to break down the plastic by hand.

- Need to take picture of Bucky in high resolution for image to base 3D printing model. Also need to accumulate proper plastics that will work for the printer. Likely sources include Memorial Union and Union South

Rather than building a filabot, it will be purchased.

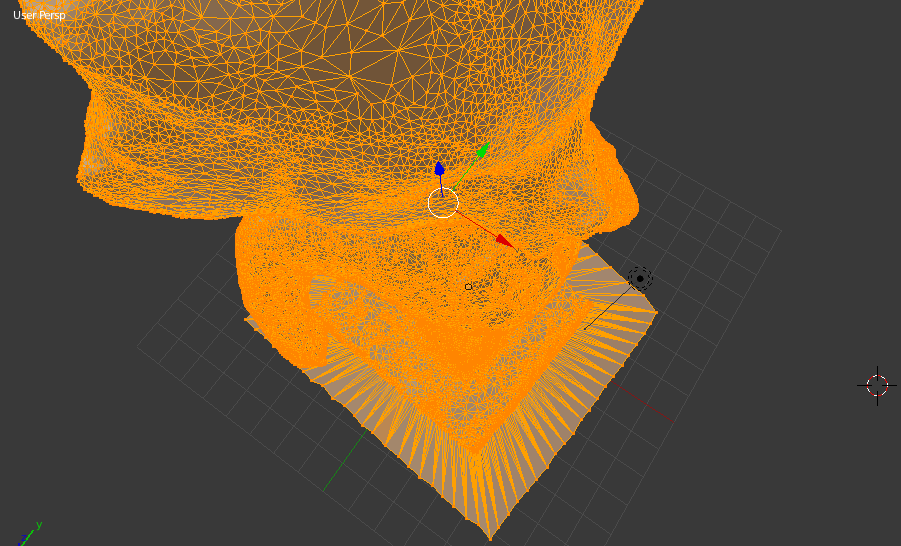

The focus of research has been honed to working on transferring photos to 3D printable images. I took into account factors like lighting, qualities of camera, and various camera angles and configurations when conducting the research.

Learning to Print:

-Below are screenshots of a Bucky Badger statue turned into a 3D printable image created with the software Autodesk 123D along with Blender.

Preliminary Trials:

Improvements:

Changed the lighting of the photo (correction just different lighting)

(A trial was conducted using a digital camera borrowed from the library for experimenting with a different camera with a different megapixel count. Results pointed towards the digital camera being less effective than other camera. Images imported to autodesk ultimately created a 3D image that was not consistent throughout.)

Final Design:

How do you turn photos into 3d? Photos to 3D.

Safety:

- The plastic will have to be broken down to a grade that will make filament creation possible. Other projects have used custom made machines for breaking down the plastic, however we are debating on how to do so using tools from the lab. Cutting tools always have a hazard associated with them, so proper precautions must be taken. Also, since the pieces are small, it must be ensured that no one has their fingers close to the machines when they are operating to hold them in place. However, there are also designs for building machines to grind up plastics that are online. If so, then the dangers are minimized, however there are still some electrical risks present. The building machine will run on electrical power so there will need to be precautions taken for safety.

Sustainability:

- Ultimately, this project can prove that you can print and recycle simultaneously with a minimal carbon footprint. By creating the plastic bottle into filament, nearly anything can be printed from a recreation of the bottle to a far more complex object. This project also goes alongside many other sustainability related projects that involve 3D printing.

Journals

Reade, Lou. "3D print: shaping the future.." Chemistry and Industry. 8 (2011): 14-15 http://web.ebscohost.com.ezproxy.library.wisc.edu/ehost/search/advanced?sid=c853497b-0e40-4046-8fed-5c6f04940ab8%40sessionmgr4002&vid=2&hid=4109

Thilmany, Jean. "The 3-D printing of living organs for transplant isn't far-fetched; it's almost here."Mechanical Engineering. 134.1 (2012 http://web.ebscohost.com.ezproxy.library.wisc.edu/ehost/detail?sid=c2a775c3-266b-4309-b21f-c7d4d0846d1a%40sessionmgr4002&vid=1&hid=4109&bdata=JkF1dGhUeXBlPWlwLHVpZCZzaXRlPWVob3N0LWxpdmUmc2NvcGU9c2l0ZQ%3d%3d#db=mth&AN=70786941

Pyper, Julia. "Can the 3-D Printer Help Green the Auto Industry?." Scientific American http://www.scientificamerican.com/article.cfm?id=can-the-3d-printer-help-green-the-auto-industry&page=2

Kim, Sandra, Matt Golding, et al. "The Application of Computer Color Matching Techniques to the Matching of Target Colors in a Food Substrate: A First Step in the Development of Foods with Customized Appearance." Journal of Food Science. http://onlinelibrary.wiley.com.ezproxy.library.wisc.edu/journal/10.1111/(ISSN)1750-3841;jsessionid=D3656E75AB80750543EE58B7152F24F9.f02t02?systemMessage=Wiley+Online+Library+will+be+disrupted+on+7+December+from+10%3A00-15%3A00+BST+%2805%3A00-10%3A00+EDT%29+for+essential+maintenance

Archer, Richard, Matt Goulding, et al. "Food Layered Manufacture: A new process for constructing solid foods." Trends in Food Science & Technology http://www.sciencedirect.com.ezproxy.library.wisc.edu/science/article/pii/S0924224412000921

More 3d printing

KickStarter Scanner: https://www.kickstarter.com/projects/621838643/desktop-3d-scanner?ref=live https://www.kickstarter.com/projects/568411200/rubicon-3d-scanner?ref=live

Ending World Hunger? http://qz.com/86685/the-audacious-plan-to-end-hunger-with-3-d-printed-food/

3D Printed Food http://www.nytimes.com/2013/09/22/opinion/sunday/dinner-is-printed.html

Add your name here to participate: