Nick Brewer

2/8/17

Some RF power from the VCO seemed to be getting through even when it was not being triggered by the delay box. Also, when the VCO was connected to the 15 V supply it seemed to add noise to the SHG error signal. So I took it out and now I'm just using the RF generators to look at one frequency at a time.

I think the backburned peak I'm trying to see EIT on is too wide. A rough calculation is showing that the EIT peak should be a couple kHz wide, and the backburned peak is closer to 4 MHz. I'm trying to narrow it by adjusting the time and power that go into creating it.

It's difficult to get more than ~1.4 W of green light from the SHG cavity and have it be stable for a while.

The best bet might be focusing the beams tighter to get more intensity in the EIT beam.

1/30/17

Been trying to see EIT. No luck yet.

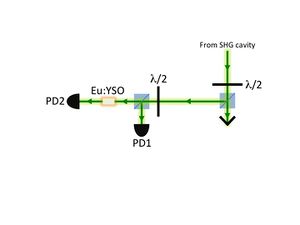

There is around 1.3 W of 527 nm light coming out of the SHG cavity. The beam goes through one beam splitter and as much light as possible is reflected, the remaining transmitted light is enough for the repump beam. The next beam splitter again reflects as much light as possible, this reflected beam goes to the control beam AOM. The remaining transmitted light through the second beam splitter is enough for the probe and goes to an AOM in a double pass configuration (so if I sweep out a spectral hole 20 MHz wide, the RF generator only sweeps over a 10 MHz range).

I try to keep the maximum RF power going into any AOM less than 5 W (37 dBm).

The control and repump beam are coupled into the same fiber using a polarizing beam cube and a polarization maintaining fiber. The output of the fiber is sent through a glan taylor polarizer and a 1/2 wave plate. The probe is also sent through a fiber with a glan taylor and 1/2 wave plate at the output. There is about a microwatt of repump and probe power. I have seen control beam powers before the crystal up to 350 mW. If the RF is on for any length of time the fiber seems to become misaligned (presumably from the AOM heating up) so the power needs to be checked quickly. The beam can be walked through the fiber at low power, and optimized by using the delay box to send short (~10 microsecond) pulses through at a time that can be seen on a photodiode.

The two beams are directed parallel to each other, but horizontally displaced by ~3/4 inches, and sent through a 200 mm lens so that they focus and overlap each other in the crystal. This geometry is used so that the probe can be separated from the control/repump beams. There is another 200 mm lens on the other side of the crystal to recollimate the beams.

I keep the cryostat between 4.5 K and 5 K mostly by adjusting the pressure in the dewar. I try to keep the pressure around 3 psi, and at this pressure the cryostat is around 5 K. Over the course of a few hours the pressure gets closer to 6 psi at which point the cryostat is usually close to 4.5 K. At that point I vent it back to 3 or 4 psi.

I have a Matlab program that controls the delay box and the RF generators to the probe, control, and repump beams.

RF1 is the probe

RF2 is the repump

RF3 is the control

RF2 is on all the time except when the EIT sequence is executed. I start by sweeping out a 20 MHz wide spectral hole for 5 seconds with the probe beam at the max RF power (+5 dBm for the current RF generator and amplifier). Then for one second I turn on the control beam at -30 dBm. At this point a spectral hole should be swept out and a backburned population with width of ~2 MHz should be in the middle of the trough.

An RF switch changes the input to the probe to a VCO instead of the RF generator. An integrator integrates a 10 microsecond pulse from the delay box to create a triangle wave, which is used as the tuning voltage of the VCO. The circuit is built so that the offset and amplitude of the triangle wave can be adjusted by potentiometers, therefore changing the range that the VCO scans over.

1/4/16

Still no Rabi flopping. There is a ~700 Hz noise on the SHG cavity that I was unable to filter out with a circuit. I tried to soundproof the box as best I could and it still didn't work. It seems like it is the resonance of the mirror mount the piezo is on. So there are a couple things we could try to solve that problem. The easiest would be to get a new mirror mount, but the layout of the cavity kind of limits the what mirror mounts we can use. Other ideas are: add weight to the mirror mount to change the frequency or use something other than a mirror mount (like just a metal block) to mount that mirror if we have enough degrees of freedom to still align the cavity.

7/24/15

After many months of seemingly doing nothing we are maybe on the cusp of seeing some original science. We can get up to 40 mW of green power at the crystal and can see the fluorescence using a photodiode and the the SRS current amplifier. If we flash a pulse ~1 us long we can detect the fluorescence and hopefully build up a rabi frequency sine wave. There is a large 60 Hz noise that averages out but there is a 300 Hz noise that we will need to figure out the source of and eliminate before we get any reliable data. We are also in the process of setting up another AOM so we can have a probe beam that is completely independent of the Rabi beam. Previously we used a pick off from the Rabi beam for the probe beam which would mean the probe would have to be on at the same time.

7/24/15

We are trying to get a square root graph.

For a 0.866 MHz wide hole, only 0.6% of the sweep beam is being transmitted.

We should be able to convert a voltage on either the Thorlabs PDA36A or the blue photodiode we are using with the SRS amplifier to a power now.

5/8/15

We finally got the ULE cavity back two days ago and it is pumping down right now. Hopefully we can just replace the invar cavity we have been using and it will work right away.

All the electronics can be controlled by Matlab now, so once the alignment is done and the laser is working at the right wavelength, we should be able to do most things by just writing a program.

When the seasons change and the humidity changes it really messes up our laser. I want to try to some how seal the laser box and pressurize it with dry air so the humidity doesn't effect it as much. I talked to some people in Saffman's lab about this and they said in the past they have just used a small pump from a fish tank and a tube with desiccant (like these) to pressurize the laser and it worked pretty well.

4/14/15

I've been hooking up all of the equipment that can be hooked up to the computer and writing some Matlab programs to control them. Right now the three RF generators, the delay box, the cryostat temp controller, and the oscilloscope all can be computer controlled. It should be a lot more convenient to control everything and get data from the oscilloscope now.

3/18/15

We discovered that the fast feedback on the PDH lock box was too high and significantly broadening our laser linewidth. Also, the driver we were using seemed to be broadening our linewidth. We switched to one of the Newport current drivers and the linewidth decreased significantly. It used to be a couple MHz wide, but after attenuating the fast feedback and changing the driver it is now around 500 kHz. This is still wider than I was thinking it was going to be, maybe the Newport driver is noisier than we would like. At some point we are planning on testing David's Vescent current driver to see if that decreases the linewidth even more (David says his linewidth is ~100 kHz unlocked). Also maybe the ULE cavity will have a higher finesse and narrow the linewidth (I measured the invar cavity to have a finesse of ~700, whereas the ULE cavity is suppose to have a finesse of 3000).

Another problem we were having was not being able to see signs of spectral hole burning when the beams were focused in the crystal. I tried seeing spectral hole burning with several different beam diameters in the crystal. I used 10 uW of power and just changed the diameter of the beam. For each intensity I set the probe to a single frequency, then shined it on the crystal and watched the fluorescence through the side viewport until I could see that the beam make it all the way through and then blocked the beam so the hole wouldn't widen if the laser moved. I scanned the laser over a 20 MHz range with 100 kHz step size and 3 ms dwell time with the same 10 uW power. The spectral holes were between 3 and 4 MHz wide. Above intensities of .6 mW/cm^2 the scanning itself began to burn holes more quickly and at intensities of 2 mW/cm^2 I wasn't able to average any more because more than one scan widened the hole noticeably (even the first scan may have widened it but how else could you check to see if a hole was there?). Quickly after 34 mW/cm^2 of intensity a single scan was enough to just burn the entire scan width and no holes were seen. The papers about Pr:YSO operate at a much higher intensity than this so I will have to think more about how the other beams pump population back into the preferred ground state. Before each new intensity I heated the crystal up to 17 K and brought it back down to 5 K. This seemed to be the minimum temperature needed to erase a spectral hole.

3/5/15

The AOMs are now set up so that the control and probe beams connect the top two ground states to the top excited state and the repumper connects the bottom ground state to the bottom excited state. This way we should be able to leave the repumper on during our experiments in order to continually pump out the unused ground state. I tried to see EIT a few times but was unsuccessful. I tried to replicate Hemmer's papers where they see EIT in Pr3+:YSO, I calculated intensities incorrectly so I was an order of magnitude higher than I thought. I'll fix it and try again. The laser doesn't seem to be as stable as you would guess when it is locked to the invar cavity. It definitely drifts with temperature. The spectral holes still drift a little but not as much as no lock. It might be that we won't be able to see anything until we get the ULE cavity back.

The SHG cavity peaks become distorted around 1 W of input power. Once the cavity is locked the power fluctuates over several hundred mW (depending on the input power). In order to stabilize it you need to adjust the error signal offset, and to a lesser extent the piezo gain, while it is locked. It becomes increasing difficult to lock to and I can't really get a stable lock over ~3.5 W or so. Also, the efficiency drops as the input power increases. Around 1 W we see around 25% efficiency, but it decreases to ~15% closer to 3 W of input power. I am able to get a maximum of 600-800 mW of green, depending on the power meter being used. This paper talks about peak distortion at higher input powers that is pretty much the same thing we are seeing. They say they don't have a problem locking it though. We should be able to produce enough green power for now, but I would like to fix it so we can have a more stable lock at higher powers. Right now I am thinking we should redesign the cavity so that the focus in the crystal is much looser. That way the thermal effects won't be as big of a deal. I think we will be able to loosen the focus and still retain good efficiency. I will run some simulations later to see what will be best.

One of the RF Bay MPA-40-40 4 Watt RF amplifiers seems to not be working right. When we scan the probe the oscilloscope trace doesn't look at smooth as it should be. There is a significant drop in green light at 80 MHz. When I switch amplifiers it looks right. For now I just switched the probe's amplifier and put the malfunctioning one on the repump AOM.

2/16/15

The idea of using the UV diode to 'reset' the 7F0 ground state seems to not work. We had hoped that by shining the UV light on the crystal we would pump the atoms to a highly excited state. Then when they fell back down to the ground state they would be evenly distributed between the three hyperfine levels. I focused the UV light onto the crystal and positioned it so the fluorescence was maximized. I burned a hole the usual way and then shined the UV light on the crystal to try to erase it. It didn't seem to do anything even when left on for an hour. I tried to erase the hole with the UV light both while the probe beam was still scanning so I could see if the hole was diminishing and while shutting the 527 nm light completely off. The UV diode is a 2 Watt diode and comes with an adjustable collimating lens. I adjusted the lens so that instead of collimating the light, it was focused on the crystal. The focused light though is still wider than the crystal so maybe there isn't enough intensity for this to be effective. I was able to reset the atoms by heating the crystal up to between 40K and 50K. I did this by adjusting the set point on the temperature controller. It only took about 5 minutes to heat up and cool back down, so maybe this isn't a terrible way of doing things if we need to.

We might not even need to reset the levels. I was pretty consistently able to sweep out a hole, back burn in a peak with the control beam and the repumper, sweep the hole again and repeat the back burning. After realigning the beams, I was able to repopulate the center of a swept out hole about 50%. This was looking at the absorption, not the fluorescence. I was looking at the absorption of the probe beam at around .4 mW and it still looked like I was putting around 50% back in the hole. This seems like a pretty high power, it didn't seem to sweep the hole back out, but I did decrease the dwell time on the sweep from 10 ms to 3 ms so maybe it isn't on long enough. Maybe this is still too low of a power and we are still getting fully absorbed at the edges of the scan.

Also, those mystery mirrors that came from surplus that we thought worked at 45 degrees for green were not reflecting very well for the control and repumper. There was about 8 mW before the two mirrors and only about .2 mW after. Maybe I didn't have them set up at 45 well enough, because they are working for the probe beam fine. Instead of messing around with them I just replaced them with silver mirrors.

1/30/15

The 1055 nm laser is now locked to a cavity (not the ULE cavity, that is still being repaired) and we are using the fiber amplifier instead of the tapered amplifier. We tried to burn a spectral hole yesterday and we are definitely seeing something but the hole seems to be ~10 MHz wide or so. We are expecting it to be the line width of the laser. Once the interferometer is running again we will have a better idea of what that is. In order to see the spectral hole we saw we were burning with upwards of hundreds of microwatts and scanning with 1 microwatt.

7/22/14

We tried to see some absorption again yesterday. The data is here, and looks unconvincing. There is not a strong peak at 1055.076 nm like we are expecting. I think in order to get a better spectrum we will need to measure fluorescence from the crystal like in Shen's paper instead of trying to directly measure absorption. Zach has been working on the locking circuit and we are now able to get a much less noisy signal. The fast feedback is fed directly to the diode instead of going through the current driver. Before the signal fluctuated ~25% or more when locked but now it is much less and we are able to get a clean signal out. There are still certain wavelengths where the error signal looks more like a peak than a dispersion graph and we are unable to lock, but we haven't yet determined the cause.

Today we found how to improve the error signal when it was mysteriously becoming distorted. Because the SHG cavity has a birefringent element, the error signal looks like two dispersion curves instead of just one. These two curves have opposite slopes when they cross zero and occur because the e- and o- polarized light each are resonant at different cavity lengths. If the cavity's birefringence changes, the two dispersion curves move relative to each other. When the two overlap the error signal you are trying to lock to is distorted and you can't get a good lock. By changing the birefringence of the cavity you can separate these two curves from each other. This can be done by changing the temperature slightly or by adding a half wave plate into the cavity. Adding the half wave plate adds a lot of loss to the cavity though so it probably isn't good for efficiently converting green light. Since the conversion efficiency is also strongly affected by the temperature, it might seem like a bad idea to change the temperature from the optimal temperature. I found the temperature bandwidth of the PPKTP crystal to be ~2.4 °C so we have a degree or so to work with before significantly affecting the conversion rate, which I think should be plenty in order to separate the error signals.

When only the fast feedback is on we can still see oscillations on the order of hundreds of Hz on the plateau of the cavity peaks. By changing the diode driver current we can make these oscillations appear and disappear (at the expense of slightly changing the wavelength). We still need to determine exactly what is causing these oscillations.

7/18/14

We tried to see some absorption yesterday. We saw fluorescence at the wavelengths we expected to, but the numbers from the photodiodes aren't too convincing. Our setup is shown to the right. For each wavelength of light we took the ratio of the photodiode signals. Scanning over the wavelength was not done too systematically. We tried to get as many wavelengths as we could close to where the peaks should have been. We adjusted the wavelength by adjusting the grating angle, current, temperature, and piezo. We saw fluorescence at wavelengths near the peak, but the quantitative data does not look as good. Our results are shown here.

6/27/14

This week we got liquid helium and cooled the cryostat down. Everything seemed to be working. We currently have no way of monitoring how much liquid helium we use though so it might be nice to come up with a way to do that.

After playing with the PID settings on the temperature controller I was able to keep the temperature mostly at 5.00 K +/- 0.01 K, which is what Janis said we should expect for a stability. The PID settings for this were: P=220, I=50, D=0 with the heater range set to medium. Once in a while it jumps out of this range though. We can probably get it better than what it is now though. Hooking the temperature controller up to a computer so we can see a graph of temperature vs time might help us more fine tune the PID settings. The flow rate of the LHe probably is a big factor in how stabilized the temperature is. So far the only way we have to control the flow rate is the flow regulator valve on the transfer line. Once the cryostat is cooled down to ~4.5 K I close the valve until the temperature starts to rise, then slowly open it until it begins to drop again. If it can't make it back to ~4.5 K I open it a smidgen more, etc, until it just reaches 4.5 K. It's not as easy as that though, there seems to be quite a bit of lag in the control, especially when it is at it's minimum temperature. I closed the flow regulator valve and tried to get the same flow rate to see if the temperature stabilized again and it did. I think you can feel the LHe flow while adjusting the valve so you can feel if it is flowing or not. A master sensei could probably use his sense of touch to adjust the flow rate.

5/30/14

The cryostat was pumped down to 1.9E-5 mbar this morning.

After closing the butterfly valve and shutting off the pump, the pressure went down to ~4E-4 mbar almost immediately. After 15 minutes the pressure was at 8.6E-3 mbar. After 20 min it was at 1E-2 mbar.

It might be best to have the pressure gauge directly attached to the 'instrumentation skirt' of the cryostat. There are blank flanges we could have a KF-25 flange put on.

5/29/14

I hooked up the turbo pump to the cryostat today. The pumping station is pretty easy to use. It was running for maybe an hour and got to 1.6E-4 mbar. I left it run overnight. Dan Logan from Janis said the cryostat can hold ~1E-4 torr and if we continually pump it with the turbo pump we can maybe get 1E-5 or 1E-6.

5/23/14

Today the cavity is working great. There were a few small peaks between the 0,0 peaks but they were small and I was able to get rid of them by adjusting the mirrors and mode matching lenses. Yesterday's problems might have been a laser issue due to the weather. This morning the humidity was 30%, I'm not sure what it was yesterday but I should keep an eye on how that affects how well the cavity is behaving.

I must have done the measurement wrong on 5/21/14. Today I measured the same finesse that I got two days ago (~65.5). I looked at the reflected signal before it went through the beam cube and got a similar measurement for (5.4/7.02 = 0.769). I think the reflectivity needs to be measured once the temperature is optimized for green generation. When I did this I got (accounting for a 106 mV noise the photodiode was seeing).

I redid the mode matching calculation with g=0.953, , and . With this numbers I get . This is good because it means the cavity is mode matched pretty well, and also that the cavity must be pretty well impedance matched. If the impedance matching is perfect, I think the mode matching coefficient, m, is just . In this case, .

According to my Matlab program, we should expect 15.9% conversion efficiency. I was getting 10 mW of green for 65.5 mW of IR, which is 15.3%.

Josh has a plastic 1" optics adaptor for the piezo we are using, so we can try that to see if it increases the resonant frequency at all. We replaced the piezo holder and the resonant frequency is almost the same. It is ~450 Hz now and was 420 Hz with the home made mirror mount.

5/22/14

I think the mode matching calculation I did was wrong because the value should definitely just be 1.01/1.21. When I looked at the reflected beam I was just using one of the photodiodes from the analyzer so it's possible that messed up the measurement. I will try to look at the cavity dips before it goes through the beamcube and redo the calculation. Regardless of what the calculation says, the amount of green we were generating is promising.

Today there were two extra peaks showing up that I couldn't get right of. One was the same height as the 0,0 mode and the other was less than 25% of the 0,0 mode. The usual alignment procedure didn't solve the problem. Moving around the mode matching lenses didn't help much either. I checked the laser on the spectrum analyzer (which is currently not working great), and the wavemeter. Both seemed to indicate it was single mode.

5/21/14

I'm interested in measuring how well the cavity is mode matched. According to Jinlu's thesis, to measure the mode matching coefficient , you can use the formula

there are three things you have to measure:

- The input coupler reflectivity with the cavity blocked

- The finesse of the cavity to determine |g| using

- The reflection dip percentage

A couple days ago I shined 84.1 mW of 1055 nm light through the input coupler and measured 4.4 mW transmitted, that corresponds to an input reflectivity of = 0.9476. I tried to measure the reflection off of the flat surface of the input coupler to account for that but I was unable to see anything; the reflected beam was too big and bright. In the future I should try again with less power.

After aligning the cavity today I measured the finesse by just looking at the ratio of the FSR to the FWHM of the cavity peaks and found = 65.5.

I also measured the cavity dips from the reflected beam and found that the dip minimum to be 1.01 V and the max value to be 1.21 V. I am confused whether 1.01/1.21 is in the formula above or if it is just .

Once the cavity was tuned and the temperature was adjusted to be at the optimal value, we measured 5.5 mW of green (I'm almost positive we used the right wavelength settings on the power meter). The input power was ~45 mW. That is an efficiency of ~12%. If I take so that and figure out the mode matching coefficient with the other measured values above, I get m=0.84 (very well mode matched...almost too well). If there is 45 mW of power before the cavity, and the mode matching coefficient is 0.84, that means that 36 mW of power is being coupled into the cavity. When I ran the Matlab code I wrote to simulate the cavity enhancement, I find that for and input coupler with T=0.05, we should expect ~12% efficiency. This result is so close to what we measured that I almost certainly calculated something wrong. If I use , I get a mode matching coefficient of m=0.12, which corresponds to 5.4 mW getting coupled into the fiber, which is less than the green power we got out.

5/20/14

We are still using the fiber we borrowed from Saffman's group but we are anxiously awaiting the arrival of the fibers we ordered from Oz Optics.

Zach got the locking circuit working for the cavity without the PPKTP crystal, but there still seems to be a resonance at the piezo frequency (~420 Hz). I rearranged the cavity and put the crystal in it and set up the analyzer for the locking circuit with some cage mount stuff ordered from Thorlabs. It was tougher to set up the cavity with the crystal. The first attempt or two resulted in the input mirror being tilted much more than what the cavity layout we designed. In the end I determined the best way was to optimize a single pass, then put the cavity mirrors in one by one trying to follow the designed beam path as best as I could. The final mirror I put in was the input coupler. I think it's pretty critical to be hitting the center of the curved mirrors so they don't have to be tilted at extreme angles. I looked at the output of the cavity by putting a microscope slide between the two flat mirrors, this is convenient to align the cavity because there isn't enough intracavity power to see a transmission through the HR mirrors. Also it doesn't perturb the cavity a huge amount; only minimal realignment is necessary when it is removed. Once I saw a couple passes of IR with the microscope slide I could see a couple passes of the green output and used that to get a rough alignment. I optimized the cavity then by looking at the cavity peaks of the green light. I touched the two mirrors that walked in the input beam very little because for fear of moving the beam path off of the crystal.

After a playing around with the lock a little bit we eventually got the cavity locked to the laser and at one point saw ~9 mW of green (from 65 mW of IR). Because the crystal is birefringent, the error signal now looks like what they describe in Vainio's paper. The output isn't super stable when we look at it with an oscilloscope. Also, since we put the crystal in it seems like the peaks jump around instead of drifting around more slowly like they did before, so that might be hurting the lock. Zach is also adding in a fast feedback to the laser current.

The polarization that generates the most green is vertical, I determined that with a Glan Taylor polarizer. We determined that in order to properly align the cavity we need to have the temperature far out of tune so we can see the cavity peaks produced from the vertically polarized light. Otherwise there is too much loss at that polarization due to the generation of green light.

5/9/14

The fibers that we were using to clean up the tapered amplifier output were introducing power fluctuations, over the course of this week we tried three fibers:

- The first fiber we tried was single mode but not polarization maintaining (and not angle polished?) and there were power fluctuations >20%.

- The next fiber was single mode and polarization maintaining but not angle polished from Oz Optics. The same power fluctuations were occurring. We determined back reflected light was getting back through the isolators and that was causing the power fluctuations.

- We borrowed a single mode, polarization maintaining, angle polished fiber that had previously been repaired from Saffman's group. This fixed the power fluctuations seen earlier, but the output polarization rotated causing the output power to drift by 50% after a beam cube. I tried to find the correct input polarization by jiggling the fiber and watching the output power fluctuate after a beam cube, but I couldn't find a good polarization. Jared said he's seen output polarization rotate due to the wrong input polarization, but it was not as extreme as this, it only caused the power to fluctuate by ~10%. I suspect this fiber is just damaged and the repair that was previously made did not completely restore the fiber (and possibly caused the current problems?).

Jared ordered some new polarization maintaining, single mode, angle polished fibers from Oz Optics so hopefully that fixes the problems we are seeing. In the mean time I just used the output of the TA to do the single pass texts on the PPKTP crystal. The results were surprisingly close to what was expected:

Single pass efficiency: ENL=Pout/Pin2=0.0027 (Simulated ENL=0.0029)

Temperature bandwidth = ~2.4 °C (In Kumar's paper they report a temp bandwidth of 3 °C for a 19 mm PPKTP crystal at 1064 nm)

Temperature tuning coefficient = 0.0591 nm/°C (The salesman from Raicol said they measured 0.053 nm/°C for SHG at 1064 nm)

For the single pass efficiency and temperature tuning bandwidth measurements the TA was set to 1799mA and had a power of 478 mW right after the TA. While determining the temperature coefficient the TA was set at 1500 mA and had a power of 350 mW right after the TA. This power changed from wavelength to wavelength a little bit though.

5/7/14

Re-centered fiber scope lens; avoided forking fiber to the table.